Why

Choose us for both our professional solution capabilities from years in the insulation field and the time/communication cost savings from one-stop service that avoids multi-party coordination.

What

As a customized insulation factory, we offer one-stop customization services from demand communication, design-proofing to production and delivery, covering various insulation products and scenario needs.

How

We ensure service delivery and product quality through a three-step closed loop: demand breakdown for schemes, full-process quality control, and flexible delivery with after-sales support.

01

Expert Design Team

Our Red Dot-winning design team does more than polish your ideas into clear solutions — we also deeply analyze the usage scenarios behind your needs, optimize details from a professional perspective, and turn abstract concepts into tangible outcomes.

02

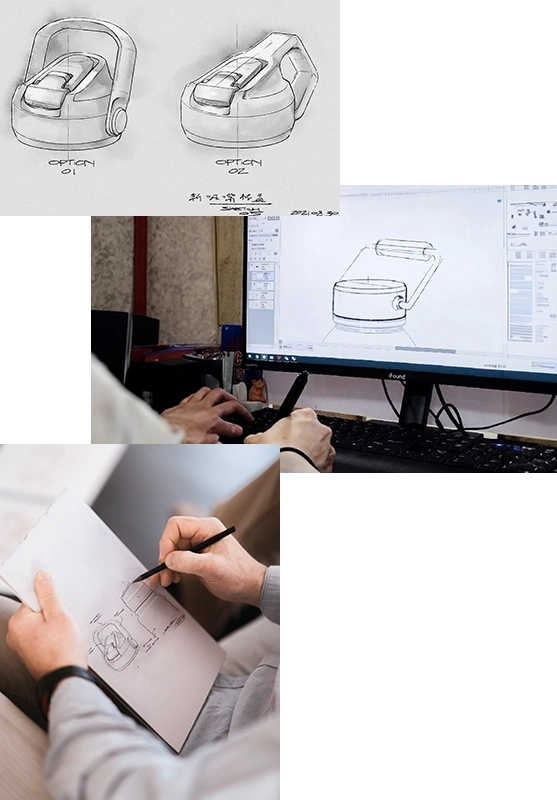

Concept Sketch

Our professional industrial designers will turn concepts into visualized appearance drawings within 5 working days as per your customized requirements. They'll create a unique and practical appearance prototype for your customized insulation products, helping you foresee the final look.

03

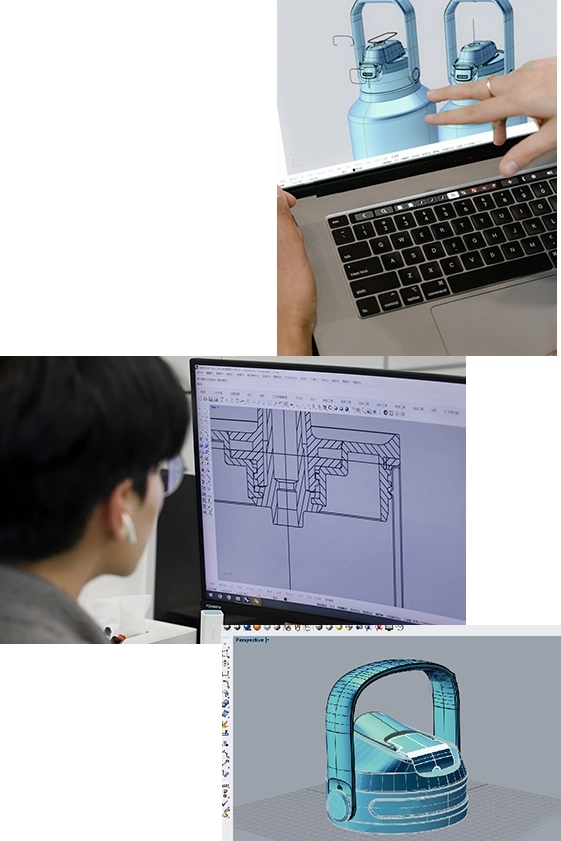

Structural Design

Our experienced team of engineers will complete the drawing of structural blueprints within 10 working days according to the appearance and functional requirements of customized insulation products. They will carefully consider all key elements to ensure that the structure is stable and reasonable, thus laying a solid foundation for production.

04

Prototype

For the customization of thermos cups, with professional techniques and equipment, we can complete the production of hand samples within 3 working days after the design scheme is confirmed, providing references for mass production and facilitating the progress of the project.

05

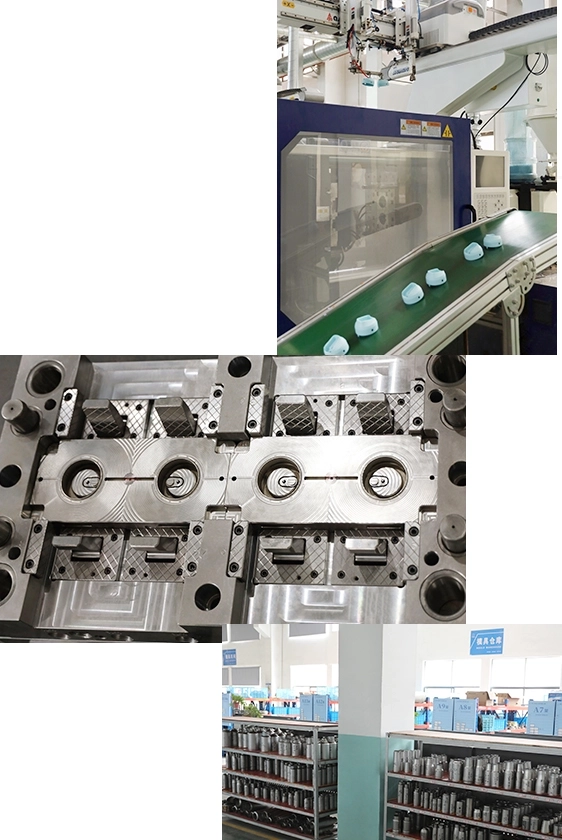

Mold Development

In the mold development process, with our professional team and advanced equipment, we can create the T1 mold that meets high standards within as fast as 15 working days after receiving the product design specifications, facilitating the subsequent mass production.

06

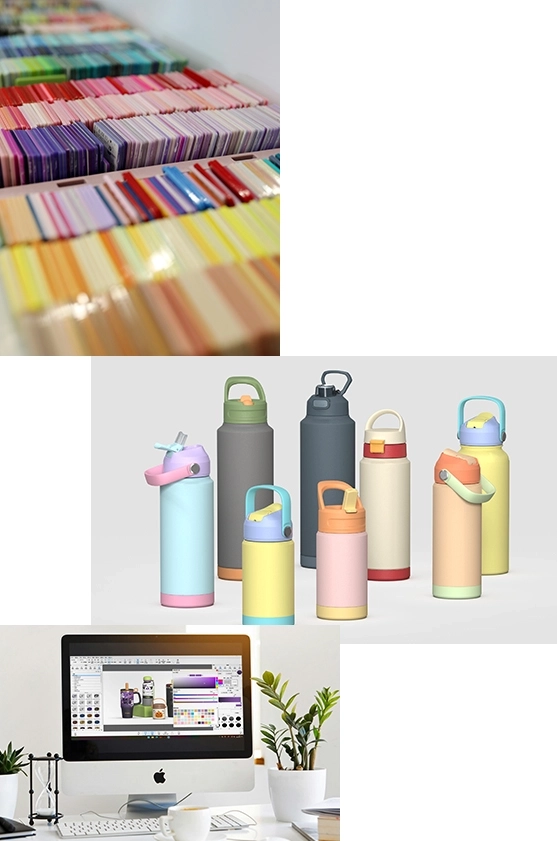

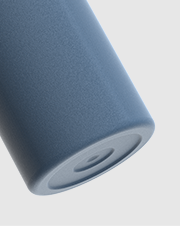

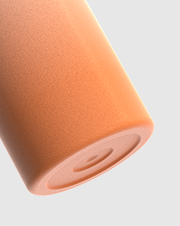

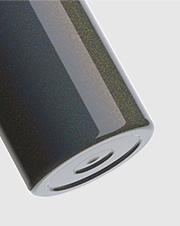

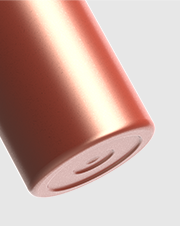

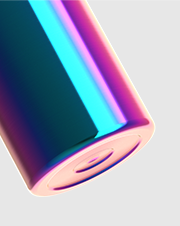

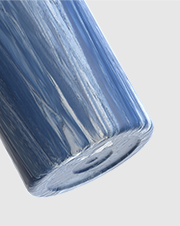

CMF Design

Our professional CMF engineering team will finalize the color and finish plans within 5 working days based on the product design framework and functional positioning, balancing aesthetics and practicality to enhance the product design.

Customize

Paint & Finishing

We are capable of carrying out operations such as spraying, powder coating, gradient ramps, 3D/4D printing, water transfer, air transfer and heat transfer. Hongling can meet all your needs.

-

powder coating

-

gradient powder coating

-

spray painting

-

rubber painting

-

rainbow painting

-

rose-gold metallic painting

-

electroplate

-

water transfer printing

-

Silk-Screen Printing

-

Laser engraving

-

Digital Printing

-

Em/Debossing

Customize Printing

brand Logo

We can customize your own brand logo. We are available to make silkscreen prints, laser engraved, embossed logo, heat transfer print, 4D print, sublimation transfer, etc to represent your company’s personality and brand.

Customized Processing Flow

Based on customers' customization requirements for insulation products, we meticulously arrange each processing step, rigorously control quality inspections, ensure processing meets standards, and achieve high-quality delivery.

OEM / ODM

Produce according to the drawings

Produce according to the specified materials

Semi-finished product processing

-

Choose Style

Confirm Size

-

Confirm the samples

The cycle is 7 to 10 days.

-

Bulk production

Put into production

-

Arrange shipment

After-sales protection